Item Added to Your Cart

Customers also bought...

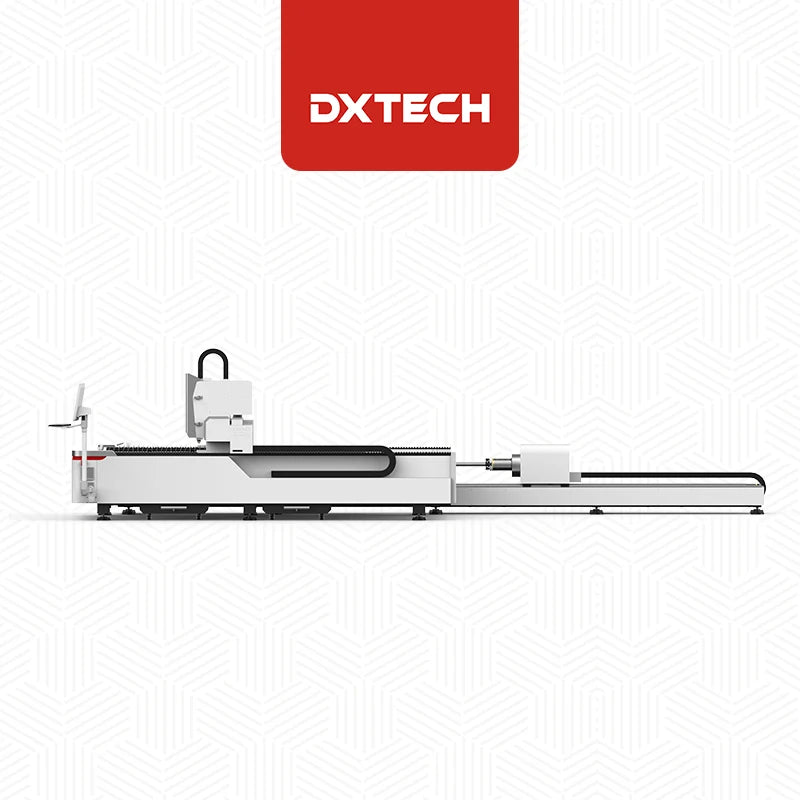

Best Quality Fiber Laser Cutting Machine Exchange Table 3kw Cnc Sheet and tube Iron Plate 3015 Price

Best Quality Fiber Laser Cutting Machine Exchange Table 3kw Cnc Sheet and tube Iron Plate 3015 Price

$33,696.00

Color/Power/Plug Type|Ships From

Item Added to Your Cart

Customers also bought...

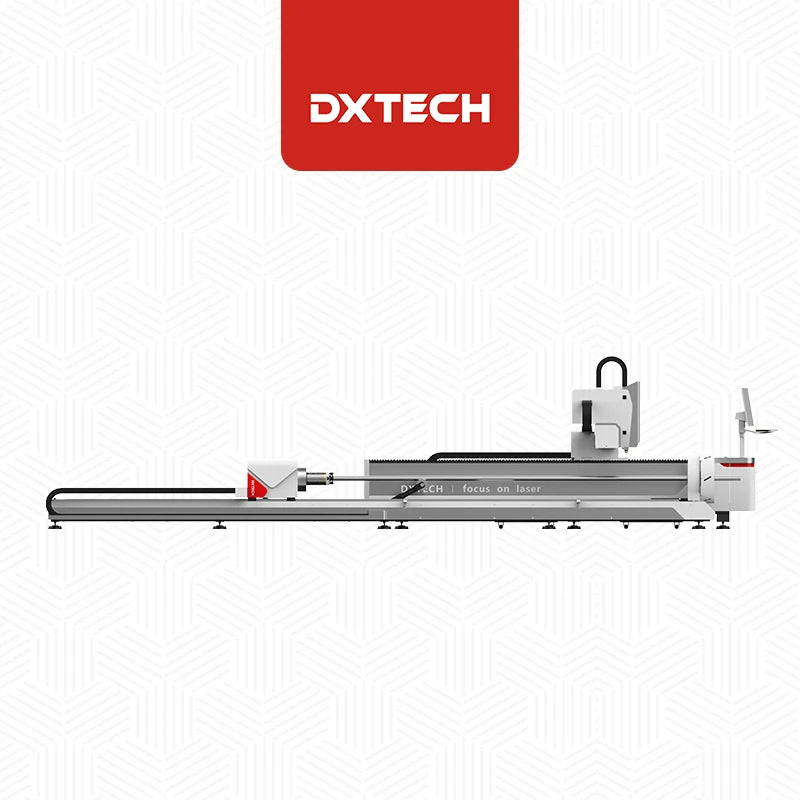

Best Quality Fiber Laser Cutting Machine Exchange Table 3kw Cnc Sheet and tube Iron Plate 3015 Price

Best Quality Fiber Laser Cutting Machine Exchange Table 3kw Cnc Sheet and tube Iron Plate 3015 Price

$33,696.00

Color/Power/Plug Type|Ships From

Item Added to Your Cart

Customers also bought...

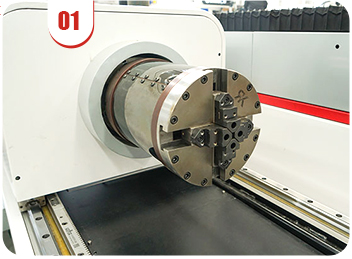

Best Quality Fiber Laser Cutting Machine Exchange Table 3kw Cnc Sheet and tube Iron Plate 3015 Price

Best Quality Fiber Laser Cutting Machine Exchange Table 3kw Cnc Sheet and tube Iron Plate 3015 Price

$33,696.00

Color/Power/Plug Type|Ships From

3

visitors right now

3

visitors have this item in their cart right now

3

people have bought this item

3

% of people buy 2 or more